info@bagadiapetrochem.co.in - GST NO. : 27AATPB6311L1ZI

50 Kilogram (MOQ)

| Business Type | Exporter, Supplier, Trader |

| Application | Pipe & Conduit Extrusion,Blow Molding Applications,Pipe & Conduit Extrusion,Etc |

| Packaging Type | Bag |

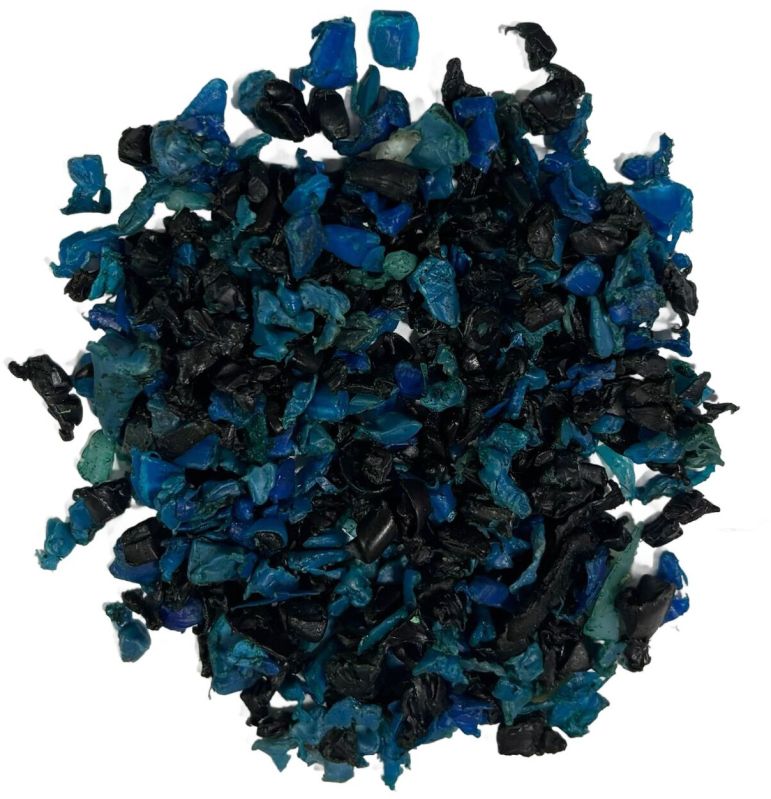

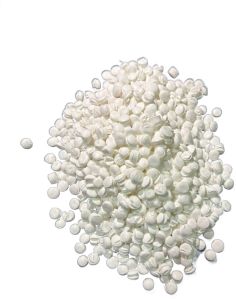

| Material | HDPE Plastic |

| Click to view more | |

Product Details

Country of Origin

India

Plastic Type

HDPE

Recommended Melt Temperatures

190-220 Degree C.

Recycled HDPE is a high-strength, durable thermoplastic made from post-consumer or post-industrial waste, commonly used in non-critical applications like pipes, containers, and plastic lumber

Looking for "HDPE Granules" ?

Kilogram