info@bagadiapetrochem.co.in - GST NO. : 27AATPB6311L1ZI

50 Kilogram (MOQ)

| Business Type | Exporter, Supplier, Trader |

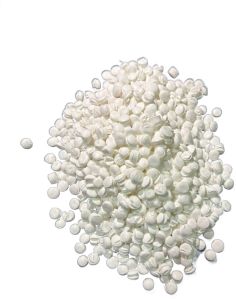

| Material | LDPE (Low-Density Polyethylene) |

| Color | Natural (Translucent) |

| Packaging Type | Bag |

| Click to view more | |

Product Details

Application

Shopping And Grocery Bags,Garbage Bags And Liners,Plastic Films,Mulch Films,Pallet Wraps And Shrink Films,Pipes And Plastic Lumber,Etc

Melting Point

105-115°C

Density

0.91-0.94 G/cm³

LDPE (Low-Density Polyethylene) is a soft, flexible plastic known for its excellent moisture resistance and used mainly in bags and packaging films.

Looking for "LDPE Granules" ?

Kilogram