- Andheri East, Mumbai, Maharashtra

- GST NO. : 27AATPB6311L1ZI

- +91-9930218498

| Business Type | Exporter, Supplier, Importer |

| Material | HDPE |

| Packaging Type | BOPP Bags |

| Shape | Granuales |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

DESCRIPTION

BorPure™MB6562 is a multimodal, high-density polyethylene intended for both injection and compression moulding. This grade combines good organoleptic properties and very good flow properties with a controlled torque level due to the incorporation of slip agent.

The broad molecular weight distribution guarantees superior environmental stress crack resistance.

CAS-No. 25087-34-7

APPLICATIONS

- Caps and closures for soft drinks, tea, juices and beer.

- Consumer and industrial articles with high ESCR demands.

KEY FEATURES

- Excellent organoleptic properties.

- Superior Environmental stress crack resistance

- Easy and versatile processability.

- Lubricant for controlled opening/ closing torque.

PROCESSING CONDITIONS

This product is easy to process with standard injection moulding machines, as well as on compression moulding equipment

Injection Moulding

Following injection moulding parameters should be used as guidelines:

Melt temperature: 190 - 250 °C

Mould temperature: 10 - 40 °C

Injection speed: As high as possible

Shrinkage 1 - 2 %, depending on wall thickness and moulding parameters

Compression Moulding

Following compression moulding parameters should be used as guidelines

Extruder temperature profile 160 - 195 °C

Melt temperature: 180 - 200 °C

Mould temperature: 10 - 40 °C

Shrinkage 1 - 2 %, depending on wall thickness and moulding parameters

Please contact your local Borouge representative for specific recommendations for processing conditions

FOOD CONTACT REGULATIONS

BorPure™MB6562 fulfils the food contact regulations in most countries. If required, contact your Borouge / Borealis representative for a certificate.

STORAGE

BorPure™MB6562 should be stored in dry conditions at temperature bellow 50°C and protected from UV-light. Improper storage can initiate degradation, which results in odour generation and colour changes and can have negative effects on physical properties of this product More information on storage can be found in Safety Information Sheet (SIS) for this product

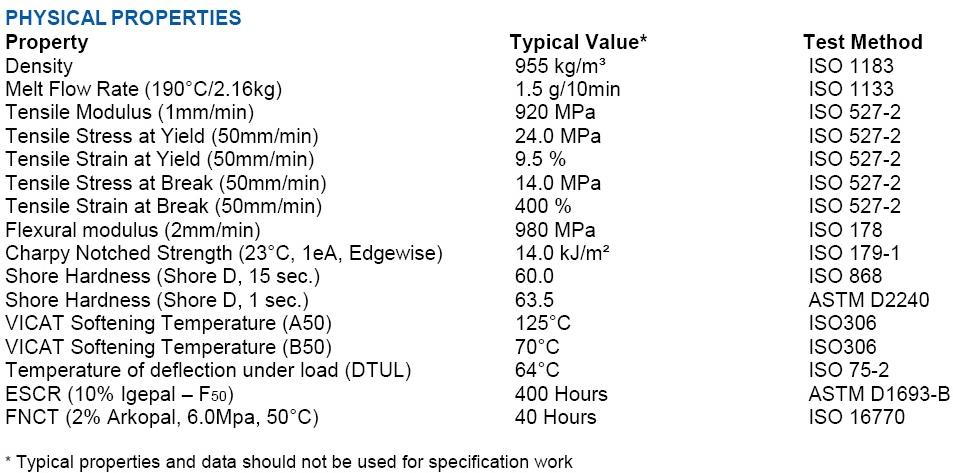

Specification