- Andheri East, Mumbai, Maharashtra

- GST NO. : 27AATPB6311L1ZI

- +91-9930218498

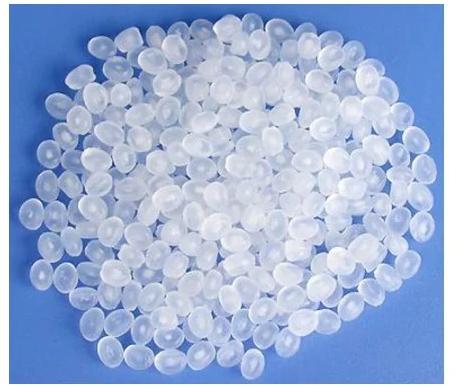

GP - Slip Granules

Leading Exporters, Wholesaler and Importer of BASELL 2427K LDPE Granules, FD0474 4MFI Qapco Lotrene LDPE Granule, Natural HP4024WN Sabic LDPE Film Grade Granules and White Natural J24FS040 Reliance LDPE Granules from Mumbai.

| Business Type | Exporter, Supplier, Importer |

| Material | Low Density |

| Shape | Rectangular |

| Color | White |

| Pattern | Plain |

| Type | Low Density Polyethylene |

| Country of Origin | India |

Preferred Buyer From

| Location | Worldwide |

Product Description

Lupolen 2427 K is an additivated, low density polyethylene. It contains an antioxidant, slip and anti-blocking agent. It is characterized by a good processability. Films made from Lupolen 2427 K exhibit good optical properties. It is delivered in pellet form.

This product is not intended for use in medical and pharmaceutical applications.

Status Commercial: Active

Availability Africa-Middle East; Asia-Pacific; Europe

Application Food Packaging Film; Hygiene Film; Shrink Film

Market Flexible Packaging

Processing Method Blown Film; Cast Film

Attribute Antioxidant; Good Heat Seal; Good Optical Properties; Good Processability; Low

Friction; Unspecified Antiblocking; Unspecified Slip

Health and Safety

The resin is manufactured to the highest standards, but special requirements apply to certain applications such as food end-use contact and direct medical use. For specific information on regulatory compliance contact your local representative.

Workers should be protected from the possibility of skin or eye contact with molten polymer. Safety glasses are suggested as a minimal precaution to prevent mechanical or thermal injury to the eyes.

Molten polymer may be degraded if it is exposed to air during any of the processing and off-line operations. The

products of degradation may have an unpleasant odor. In higher concentrations they may cause irritation of the mucus membranes. Fabrication areas should be ventilated to carry away fumes or vapours. Legislation on the control of emissions and pollution prevention should be observed. The resin will burn when supplied with excess heat and oxygen. It should be handled and stored away from contact with direct flames and/or ignition sources. While burning, the resin contributes high heat and may generate a dense black smoke.

Recycled resins may have previously been used as packaging for, or may have otherwise been in contact with, hazardous goods. Converters are responsible for taking all necessary precautions to ensure that recycled resins are safe for continued use. For further information about safety in handling and processing please refer to the Safety Data Sheet

| Business Type | Exporter, Supplier, Importer |

| Material | LDPE |

| Color | Natural White |

| Application | Industrial Use |

| Transparency | Transparent |

| Country of Origin | India |

Preferred Buyer From

| Location | Worldwide |

DESCRIPTION

Lotrène® FD0474 is mainly recommended for the extrusion of very high clarity blown and cast films. It contains both slip additives (target 600 ppm erucamide) and anti blocking additives (target 900 ppm) as well as antioxidants.

PROPERTIES

The molecular structure of Lotrène® FD0474 provides excellent clarity, high gloss and low haze films. This structure also leads to excellent processability.

PROCESSING

- Lotrène® FD0474 can be easily processed on all types of extruders designed for polyethylene.

- The melt temperature is suggested to be in the range of 140-150 °C.

- The best properties of the blown film are achieved at blow up ratios between 2:1 and 3:1.

- The recommended thickness range is from 15 μm to 100 μm.

APPLICATIONS

• High-clarity film for packaging of Luxury goods, Flowers, …

• Laundry film & garment packaging

• Food packaging (frozen food, bread bags, zip lock bags…)

• Display film

HANDLING & STORAGE

Polyethylene products should be stored in their original packaging or in clean appropriate silos. The products should be stored in a dry and well-ventilated area and should not be exposed to direct sunlight and/ or heat in any form since this may adversely affect their properties. As a general rule, our products should not be stored for more than three months from receipt date.

SAFETY

Under normal conditions Lotrène® products do not present a toxic hazard through skin contact or inhalation. For detailed information please refer to the Safety Data Sheet.

FOOD CONTACT & REACH

Lotrène® polyethylene products manufactured by Qatar Petrochemical Company (QAPCO) Q.S.C. comply with US, EU and other food contact legislations. Limitations may apply. All QAPCO Lotrène products are complying with REACH Regulation 1907/2006/EC. The aims of this regulation are to improve the protection of human health and the environment through better and earlier identification o the intrinsic properties of chemical substances.

| Business Type | Exporter, Supplier, Importer |

| Packaging Type | Plastic Bag |

| Material | LDPE |

| Color | Natural White |

| Application | Industrial Use |

| Feature | Long Life |

| Country of Origin | India |

Preferred Buyer From

| Location | Worldwide |

DESCRIPTION

HP4023WN is an antioxidant free low density polyethylene grade suitable for producing general-purpose films. It contains slip and antiblock additives. It gives excellent processability and optical properties with good mechanical properties.

TYPICAL APPLICATIONS

HP4023WN can be used for high clarity laundry bags, textile wrapping films, produce bags, zip lock bags.

PROCESSING CONDITIONS

Typical processing conditions for HP4023WN are:

Barrel temperature: 160 - 190°C, Blow up ratio: 2.0 – 3.0

STORAGE AND HANDLING

Polyethylene resin should be stored in a manner to prevent a direct exposure to sunlight and/or heat. The storage area should also be dry and preferably do not exceed 50°C. SABIC would not give warranty to bad storage conditions which may lead to quality deterioration such as color change, bad smell and inadequate product performance. It is advisable to process PE resin within 6 months after delivery.

| Business Type | Exporter, Supplier, Importer |

| Material | LDPE |

| Packaging Type | Plastic Bag |

| Country of Origin | India |

| Quality | Optimum |

| Physical State | Granules |

Preferred Buyer From

| Location | Worldwide |

These are blown film grades and can be extruded with considerable ease. J24FS040 has been blended with necessary additives during manufacture to obtain good surface slip and easy openability between two layers of the film.

APPLICATIONS:

High slip grade for shopping bag, zip lock bags, general purpose consumer packaging. Non-slip grade can be used for bubble wrap and lamination film.

Typical Process Consitions

- Melt Temperature (˚C): 160 – 200

- Recommended Blow Up Ratio (BUR): 1.5 – 3.0 (Based on applications, best results achieved with BUR of 2.5: 1)

- Die Gap: > 0.8 mm (Based on film thickness and throughput of the machine)

Regulatory Information

- Meets the requirements stipulated in standard IS: I0146 on "Specification for Polyethylene for safe use in contact with foodstuffs, pharmaceuticals, and drinking water". It also conforms to IS 16738:2018 “Positive List of Constituents for Polypropylene, Polyethylene and their Copolymers for its Safe Use in Contact with Foodstuffs and Pharmaceuticals”

- The grade and the additives incorporated in it also comply with the FDA: CFR Title 21,177.1520, Olefin polymers

Storage Recommendations

Bags should be stored in dry/closed conditions at temperatures below 50°C and protected from UV / direct sunlight