- Andheri East, Mumbai, Maharashtra

- GST NO. : 27AATPB6311L1ZI

- +91-9930218498

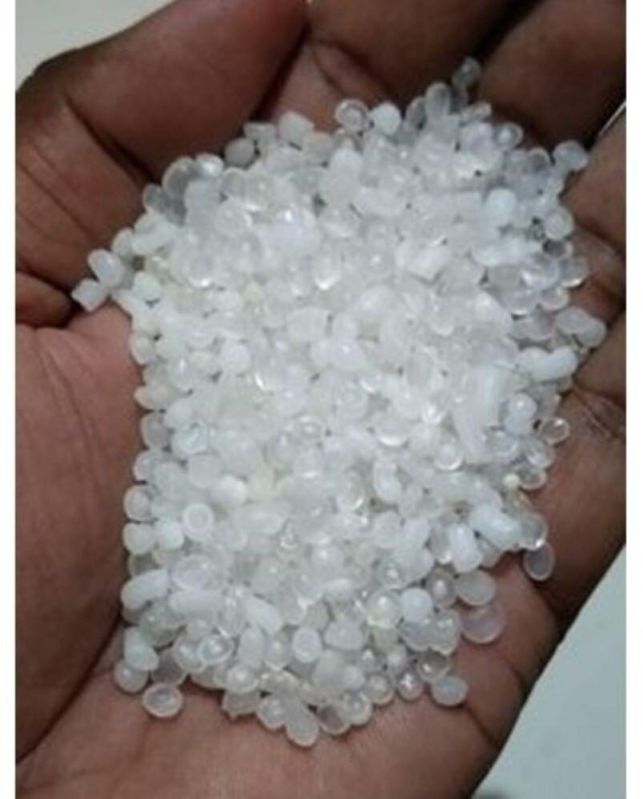

Polypropylene Mould Granules

Leading Exporters, Wholesaler and Importer of BOROUGE HE125MO Polypropylene Granuels, Borouge HG385MO Polypropylene Granule, LUBAN HP2100N PP Injection Moulding Granules, Polyethylene Solid State Luban HP2106N Granuels and White SABIC 5706P Polypropylene Granuels from Mumbai.

| Business Type | Exporter, Supplier, Importer |

| Color | White |

| Form | Granules |

| Application | Industrial |

| Type | Polypropylene Granules |

| Country of Origin | India |

| Packing Material | Packed in Plastic Bags |

Preferred Buyer From

| Location | Worldwide |

DESCRIPTION

HE125MO is a versatile polypropylene homopolymer intended for injection moulding.

This product shows very good stiffness and toughness.

APPLICATIONS

- Closures

- Houseware

- Garden furniture

- Compounds and master batches

SPECIAL FEATURES

- Good flow behaviour

- High stiffness

PROCESSING CONDITIONS

- HE125MO is easy to process with standard injection moulding machines.

- Following parameters should be used as guidelines:

- Melt temperature: 220 - 260°C

- Holding pressure: 200 - 500bar As required to avoid sink marks

- Mould temperature: 20 - 40°C

- Injection speed: High

- Shrinkage 1 - 2%, depending on wall thickness and moulding parameters

STORAGE

HE125MO should be stored in dry conditions at temperatures below 50°C and protected from UV-light. Improper storage can initiate degradation, which results in odour generation and colour changes and can have negative effects on the physical properties of this product. More information on storage can be found in Safety Information Sheet (SIS) for this product

SAFETY

The product is not classified as a hazardous preparation. Please see our Safety Information Sheet (SIS) for details on various aspects of safety, recovery and disposal of the product, for more information contact your Borouge representative.

RECYCLING

The product is suitable for recycling using modern methods of shredding and cleaning. In-house production waste should be kept clean to facilitate direct recycling.

RELATED DOCUMENTS

The following related documents are available on request, and represent various aspects on the usability, safety, recovery and disposal of the product.

Safety Information Sheet Statement on chemicals, regulations and standards Statement on compliance to food contact regulations

| Business Type | Exporter, Supplier, Importer |

| Shape | Pp Granules |

| Color | White |

| Form | Granules |

| Application | Injection Molding |

| Type | Polypropylene Granules |

| Country of Origin | India |

Preferred Buyer From

| Location | Worldwide |

DESCRIPTION

HG385MO is a polypropylene homopolymer intended for injection moulding. This product combines unique Borstar reactor design with Borstar Nucleation Technology (BNT) to produce highly crystalline polypropylene. This product is characterized by excellent flow properties combined with a narrow molecular weight distribution, well suited for low warpage products.

This product contains anti-static and slip additives, which result in short cycle time, easy demoulding and low dust attraction.

Products moulded from this grade exhibit excellent dimension consistency combined with high stiffness and gloss.

APPLICATIONS

- Caps and closures

- Appliances with great heat resistance

- Household articles

SPECIAL FEATURES

High stiffness Low warpage

Heat resistance High gloss

Shows excellent antistatic performance

HG385MO is easy to process with standard injection moulding machines.

Following parameters should be used as guidelines:

Melt temperature: 220 - 260°C

Holding pressure: 200 - 500bar As required to avoid sink marks

Mould temperature: 10 - 30°C

Injection speed: As high as possible

Shrinkage 1 - 2%, depending on wall thickness and moulding parameters

STORAGE

HG385MO should be stored in dry conditions at temperatures below 50°C and protected from UV-light. Improper storage can initiate degradation, which results in odour generation and colour changes and can have negative effects on the physical properties of this product. More information on storage can be found in Safety Information Sheet (SIS) for this product

SAFETY

The product is not classified as a hazardous preparation. Please see our Safety Information Sheet (SIS) for details on various aspects of safety, recovery and disposal of the product, for more information contact your Borouge representative.

RECYCLING

The product is suitable for recycling using modern methods of shredding and cleaning. In-house production waste should be kept clean to facilitate direct recycling

| Business Type | Exporter, Supplier, Importer |

| Shape | Pp Granules |

| Color | White |

| Form | Granules |

| Application | Injection Molding, Industrial |

| Type | Polypropylene Granules |

| Country of Origin | India |

| Packing Material | Packed in Plastic Bags |

Preferred Buyer From

| Location | Worldwide |

Description

Luban HP2100N is manufactured using Novolen vertical stirred Gas-phase polymerization process. Luban HP2100N is a homopolymer polypropylene injection molding grade. The grade exhibits good flow and stiffness.

Application

General injection molding, closures, furniture, houseware..

Processing Guidlines

The Typical Processing Conditions for Luban HP2100N are:

Melt temperature 220 – 260 °C

Holding pressure 200 – 500 bar Maximum to avoid sink marks

Storage and Handling

Luban HP2100N must be protected from direct sunlight and should be stored in a shaded and completely dry area. During handling and processing, the material should be kept in a well-ventilated area to prevent the accumulation of dust and fumes. Contact with strong oxidizers, excessive heat, sparks or open flame should be avoided as this could initiate the degradation process and consequently impact the quality of the material

Safety

Luban HP2100N is not classified as dangerous preparation. For further information about safety in handling and processing please refer to the Safety Data Sheet

Food Contact

Luban HP2100N meets the requirements of the U.S. Food and Drug Administration (FDA) as specified in 21 CFR 177.1520, covering safe use of polyolefin articles and components of articles intended for direct food contact. For additional information on approved conditions of use for food contact applications, please refer to the “Product Stewardship Declaration”.

Mold temperature 20 – 40 °C

Injection speed High

Shrinkage 1 – 2 % depending on wall thickness and molding parameters

Note: Processing parameters should only be used as guidelines. The above properties values are not to be construed as specifications

| Business Type | Exporter, Supplier, Importer |

| Shape | Pp Granules |

| Country of Origin | India |

| Packing Material | Packed in Plastic Bags |

Preferred Buyer From

| Location | Worldwide |

Description

Luban HP2106N is manufactured using the Spheripol Technology. Luban HP2106N is a homopolymer polypropylene used for general purpose injection molding applications. It exhibits good flow and stiffness. Luban HP2106N is suitable for food contact.

Application

General purpose injection molding, closures, furniture, houseware

Note: These are typical properties only and are not to be construed as specifications. Users should confirm results by their own tests.

The Typical Processing Conditions for Luban HP2106N are:

Melt temperature 220 – 260 °C

Holding pressure 200 – 500 bar Maximum to avoid sink marks

Mold temperature 20 – 40 °C

Injection speed High

Shrinkage 1 – 2 % depending on wall thickness and molding parameters

Storage and Handling

Luban HP2106N must be protected from direct sunlight and should be stored in a shaded and completely dry area. During handling and processing, the material should be kept in a well-ventilated area to prevent the accumulation of dust and fumes. Contact with strong oxidizers, excessive heat, sparks or open flame should be avoided as this could initiate the degradation process and consequently impact the quality of the material.

Safety

Luban HP2106N is not classified as dangerous preparation. For further information about safety in handling and processing please refer to the Safety Data Sheet.

Food Contact

Luban HP2106N meets the requirements of the U.S. Food and Drug Administration (FDA) as specified in 21 CFR 177.1520, covering safe use of polyolefin articles and components of articles intended for direct food contact. For additional information on approved conditions of use for food contact applications, please refer to the “Product Stewardship Declaration”.

| Business Type | Exporter, Supplier, Importer |

| Color | White |

| Form | Granules |

| Application | Injection Molding, Industrial |

| Type | Polypropylene Granules |

| Country of Origin | India |

| Packing Material | Packed in Plastic Bags |

Preferred Buyer From

| Location | Worldwide |

DESCRIPTION

SABIC® PP 5706P is specially developed for producing rigid injection molded articles for general purpose applications. It gives consistent processability and high gloss at the products.

TYPICAL APPLICATIONS

SABIC® PP 5706P can be used for houseware articles, food containers, furniture and toys.

PROCESSING CONDITIONS

- Typical processing conditions for 5706P are:

- Barrel temperature range: 200 - 250°C.

- Mold Shrinkage: 1.2 - 2.5% depending on wall thickness and processing conditions.

- Mold Temperature: Normally 15 - 40°C, up to 65°C for thick parts

STORAGE AND HANDLING

Polypropylene resin should be stored in a manner to prevent a direct exposure to sunlight and/or heat. The storage area should also be dry and preferably do not exceed 50°C. SABIC would not give warranty to bad storage conditions which may lead to quality deterioration such as color change, bad smell and inadequate product performance. It is advisable to process PP resin within 6 months after delivery.