- Andheri East, Mumbai, Maharashtra

- GST NO. : 27AATPB6311L1ZI

- +91-9930218498

| Business Type | Exporter, Supplier, Importer |

| Shape | Pp Granules |

| Country of Origin | India |

| Packing Material | Packed in Plastic Bags |

Preferred Buyer From

| Location | Worldwide |

Description

Luban HP2106N is manufactured using the Spheripol Technology. Luban HP2106N is a homopolymer polypropylene used for general purpose injection molding applications. It exhibits good flow and stiffness. Luban HP2106N is suitable for food contact.

Application

General purpose injection molding, closures, furniture, houseware

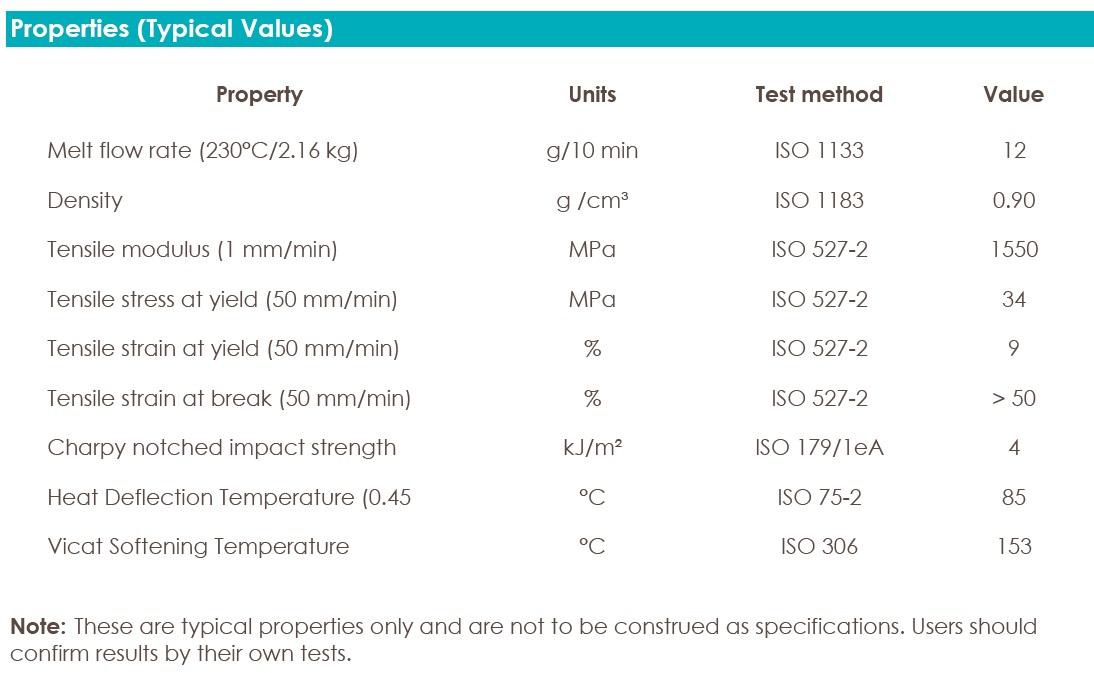

Note: These are typical properties only and are not to be construed as specifications. Users should confirm results by their own tests.

The Typical Processing Conditions for Luban HP2106N are:

Melt temperature 220 – 260 °C

Holding pressure 200 – 500 bar Maximum to avoid sink marks

Mold temperature 20 – 40 °C

Injection speed High

Shrinkage 1 – 2 % depending on wall thickness and molding parameters

Storage and Handling

Luban HP2106N must be protected from direct sunlight and should be stored in a shaded and completely dry area. During handling and processing, the material should be kept in a well-ventilated area to prevent the accumulation of dust and fumes. Contact with strong oxidizers, excessive heat, sparks or open flame should be avoided as this could initiate the degradation process and consequently impact the quality of the material.

Safety

Luban HP2106N is not classified as dangerous preparation. For further information about safety in handling and processing please refer to the Safety Data Sheet.

Food Contact

Luban HP2106N meets the requirements of the U.S. Food and Drug Administration (FDA) as specified in 21 CFR 177.1520, covering safe use of polyolefin articles and components of articles intended for direct food contact. For additional information on approved conditions of use for food contact applications, please refer to the “Product Stewardship Declaration”.

Specification